Spaceium Demonstrates Ultra-Precision Refueling Actuator in Orbit

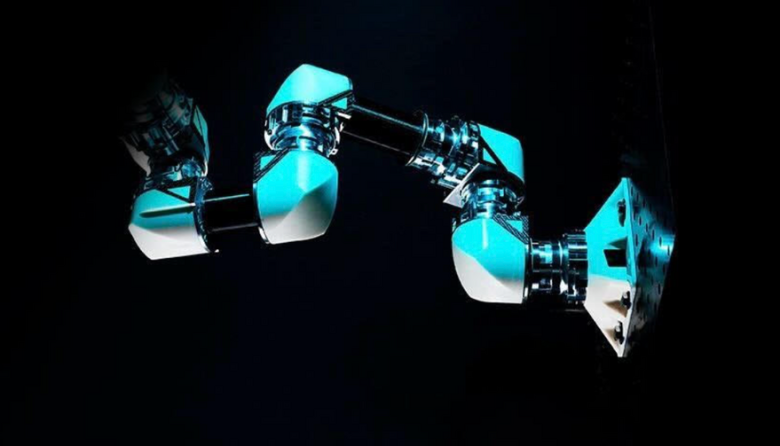

Spacieum Robotic Arm. Image Credit: Spaceium

At Hickory Falls Ventures, we invest in companies building the infrastructure for the next era of space. Today, we’re thrilled to congratulate Spaceium Inc. on achieving a landmark milestone: successfully demonstrating its ultra-precise robotic refueling actuator in orbit.

This is not a lab test.

This is not a ground simulation.

This is space.

On SpaceX Transporter-15, Spaceium flew and operated what is now the most precise robotic actuator ever tested in orbit — achieving a verified 0.003° rotation accuracy, translating to less than one millimeter of movement at the end of a five-meter robotic arm.

That level of precision has never before been demonstrated in space.

And it matters more than almost anything else for the future of in-space refueling.

Why This Milestone Is So Significant

1. In-Space Refueling Is a Massive, Inevitable Market

Satellites today are disposable — not because they stop working, but because they run out of fuel.

A communications satellite costing $200M–$400M can be rendered useless by propellant depletion alone. The same is true for defense satellites, Earth observation platforms, and future deep-space assets.

Refueling changes the equation:

Extends satellite life by years

Reduces replacement launch costs

Enables new mission profiles

Supports national security resilience

Unlocks entirely new in-orbit service economies

As launch costs fall and satellite constellations multiply, orbital servicing — including refueling — moves from futuristic concept to economic necessity.

The long-term prize isn’t a single mission.

It’s a network of automated service stations in space.

2. Precision Is the Hardest Technical Problem

Refueling another spacecraft in orbit is not docking at a gas station.

You are:

Operating in vacuum

Facing radiation exposure

Managing extreme temperature swings

Handling two objects traveling ~28,000 km/h

Aligning fuel transfer interfaces that cannot tolerate error

A robotic system must approach, align, grapple, and connect with near-perfect control.

Spaceium’s actuator is the “precision driver” of that system — the component responsible for ensuring every movement is stable and reliable.

By proving:

It survives space conditions

It performs consistently in orbit

It achieves sub-millimeter end-effector accuracy

It is 70x more accurate than current space robotic arms

Spaceium has de-risked one of the most critical technical bottlenecks in the refueling stack.

This is a foundational proof point.

3. Hardware Validation in Orbit Is Everything

In space infrastructure, ground testing is necessary — but insufficient.

True validation happens in orbit.

Spaceium:

Designed

Built

Launched

Operated

Verified performance

… all within five months.

That execution speed signals more than technical capability — it signals a team capable of moving fast in one of the most complex engineering domains in the world.

This milestone moves in-space refueling from “theoretical roadmap” to “demonstrated capability.”

4. A Stepping Stone Toward Autonomous Orbital Service Stations

The long-term vision is not one robotic arm.

It is a system of fully automated refueling depots that:

Service commercial satellites

Support defense logistics

Enable deep space missions

Form the backbone of a sustainable orbital economy

Precision actuators are the enabling component.

Without this level of control, you cannot safely and reliably transfer fuel in space.

With it, you can begin to scale.

Why This Matters for the Space Economy

At HFV, we believe the next great wave in space will not just be launch.

It will be:

On-orbit servicing

Space logistics

Infrastructure platforms

Persistent orbital assets

Reusable rockets unlocked access to orbit.

Orbital servicing unlocks durability and capital efficiency in orbit.

Spaceium is building one of the key primitives required for that future.

Congratulations to the Team

To achieve sub-millimeter robotic precision in orbit — in vacuum, radiation, and extreme thermal conditions — is extraordinary.

To do it in months, not years, is even more impressive.

This milestone proves:

It works.

In orbit.

At unprecedented precision.

Now comes the next phase: scale.

We’re proud to support Spaceium as they build the robotic infrastructure that may one day power autonomous fuel stations in space.

The orbital economy just moved one step closer to permanence.

🚀